M4E Research #16: April/May 2025

Multi-Agent Reinforcement Learning for Resources Allocation Optimization: A Survey

Abstract: Multi-Agent Reinforcement Learning (MARL) has become a powerful framework for numerous real-world applications, modeling distributed decision-making and learning from interactions with complex environments. Resource Allocation Optimization (RAO) benefits significantly from MARL's ability to tackle dynamic and decentralized contexts. MARL-based approaches are increasingly applied to RAO challenges across sectors playing pivotal roles to Industry 4.0 developments. This survey provides a comprehensive review of recent MARL algorithms for RAO, encompassing core concepts, classifications, and a structured taxonomy. By outlining the current research landscape and identifying primary challenges and future directions, this survey aims to support researchers and practitioners in leveraging MARL's potential to advance resource allocation solutions.

Authors: Mohamad A. Hady, Siyi Hu, Mahardhika Pratama, Jimmy Cao, Ryszard Kowalczyk

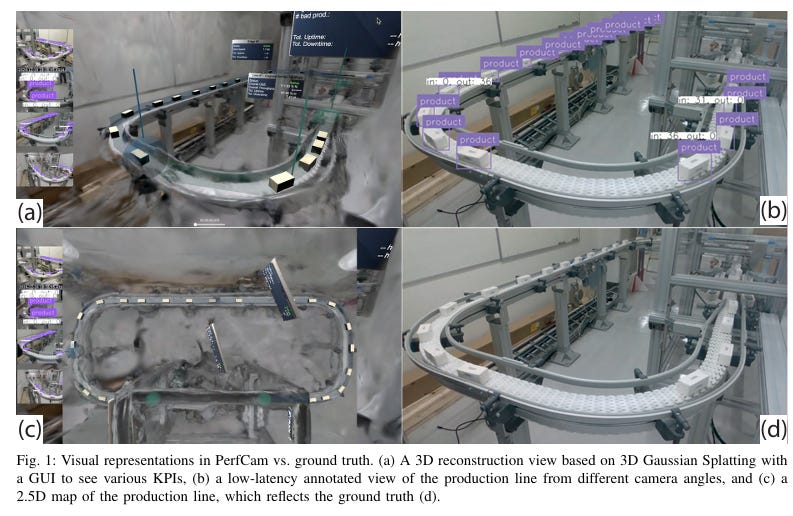

PerfCam: Digital Twinning for Production Lines Using 3D Gaussian Splatting and Vision Models

Abstract: We introduce PerfCam, an open source Proof-of-Concept (PoC) digital twinning framework that combines camera and sensory data with 3D Gaussian Splatting and computer vision models for digital twinning, object tracking, and Key Performance Indicators (KPIs) extraction in industrial production lines. By utilizing 3D reconstruction and Convolutional Neural Networks (CNNs), PerfCam offers a semi-automated approach to object tracking and spatial mapping, enabling digital twins that capture real-time KPIs such as availability, performance, Overall Equipment Effectiveness (OEE), and rate of conveyor belts in the production line. We validate the effectiveness of PerfCam through a practical deployment within realistic test production lines in the pharmaceutical industry and contribute an openly published dataset to support further research and development in the field. The results demonstrate PerfCam's ability to deliver actionable insights through its precise digital twin capabilities, underscoring its value as an effective tool for developing usable digital twins in smart manufacturing environments and extracting operational analytics.

Authors: Michel Gokan Khan, Renan Guarese, Fabian Johnson, Xi Vincent Wang, Anders Bergman, Benjamin Edvinsson, Mario Romero, Jérémy Vachier, Jan Kronqvist

Facilitating Reinforcement Learning for Process Control Using Transfer Learning: Overview and Perspectives

Abstract: In the context of Industry 4.0 and smart manufacturing, the field of process industry optimization and control is also undergoing a digital transformation. With the rise of Deep Reinforcement Learning (DRL), its application in process control has attracted widespread attention. However, the extremely low sample efficiency and the safety concerns caused by exploration in DRL hinder its practical implementation in industrial settings. Transfer learning offers an effective solution for DRL, enhancing its generalization and adaptability in multi-mode control scenarios. This paper provides insights into the use of DRL for process control from the perspective of transfer learning. We analyze the challenges of applying DRL in the process industry and the necessity of introducing transfer learning. Furthermore, recommendations and prospects are provided for future research directions on how transfer learning can be integrated with DRL to enhance process control. This paper aims to offer a set of promising, user-friendly, easy-to-implement, and scalable approaches to artificial intelligence-facilitated industrial control for scholars and engineers in the process industry.

Authors: Runze Lin, Junghui Chen, Lei Xie, Hongye Su

SmartPilot: A Multiagent CoPilot for Adaptive and Intelligent Manufacturing

Abstract: In the dynamic landscape of Industry 4.0, achieving efficiency, precision, and adaptability is essential to optimize manufacturing operations. Industries suffer due to supply chain disruptions caused by anomalies, which are being detected by current AI models but leaving domain experts uncertain without deeper insights into these anomalies. Additionally, operational inefficiencies persist due to inaccurate production forecasts and the limited effectiveness of traditional AI models for processing complex sensor data. Despite these advancements, existing systems lack the seamless integration of these capabilities needed to create a truly unified solution for enhancing production and decision-making. We propose SmartPilot, a neurosymbolic, multiagent CoPilot designed for advanced reasoning and contextual decision-making to address these challenges. SmartPilot processes multimodal sensor data and is compact to deploy on edge devices. It focuses on three key tasks: anomaly prediction, production forecasting, and domain-specific question answering. By bridging the gap between AI capabilities and real-world industrial needs, SmartPilot empowers industries with intelligent decision-making and drives transformative innovation in manufacturing. The demonstration video, datasets, and supplementary materials are available at this https URL.

Authors: Chathurangi Shyalika, Renjith Prasad, Alaa Al Ghazo, Darssan Eswaramoorthi, Harleen Kaur, Sara Shree Muthuselvam, Amit Sheth